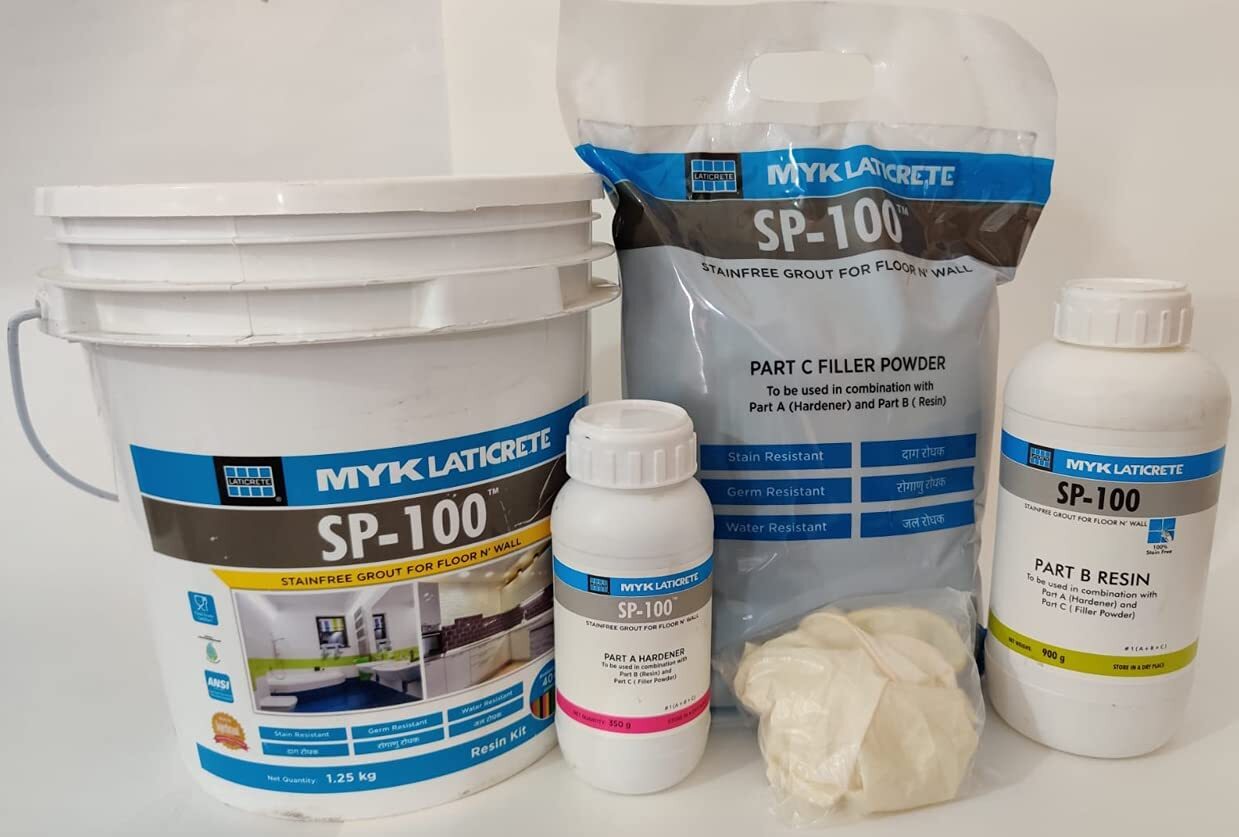

Myk SP -100 Resin Kit 0.25Kg

Myk SP-100 Resin Kit is a specialized product designed for use in conjunction with Myk SP-100 Filler. This resin kit is an essential component in the preparation of epoxy grout, providing the necessary adhesive and binding properties that ensure the grout's durability, stain resistance, and overall performance. Here’s a description:

Product Overview:

- Brand: Myk Laticrete

- Product Name: SP-100 Resin Kit

- Type: Epoxy resin

- Components: Typically includes a resin (part A) and a hardener (part B) that must be mixed together.

Key Features:

- High Adhesive Strength: Provides excellent bonding to a wide variety of substrates, ensuring the grout adheres firmly to the tiles and joints.

- Durability: The resin mixture cures to form a hard, durable surface that resists wear, cracking, and shrinkage, maintaining the integrity of the tiled surface over time.

- Stain Resistance: When mixed with SP-100 Filler, the resin contributes to the grout’s ability to resist stains from common substances like oils, grease, and food spills.

- Chemical Resistance: The cured epoxy grout is highly resistant to chemicals, making it suitable for use in environments exposed to harsh substances.

- Waterproof: Once cured, the resin provides a waterproof barrier, preventing moisture from penetrating the grout and underlying layers, ideal for wet areas such as bathrooms, kitchens, and swimming pools.

- Easy Mixing: The resin and hardener are designed to be mixed easily, creating a smooth, workable mixture that can be applied with precision.

Application Areas:

- Residential: Kitchens, bathrooms, and other tiled areas that require strong, durable, and stain-resistant grout.

- Commercial: Ideal for high-traffic areas such as shopping malls, restaurants, hotels, and office buildings.

- Industrial: Suitable for use in factories, laboratories, and other environments where chemical resistance and durability are crucial.

Application Instructions:

- Mixing: Combine the resin (part A) and hardener (part B) according to the manufacturer’s instructions, ensuring they are mixed thoroughly to achieve a uniform consistency.

- Application: Once mixed, the resin should be combined with the Myk SP-100 Filler and applied to the tile joints using appropriate tools such as a rubber float.

- Curing: Allow the mixed resin and filler to cure according to the recommended time before exposing the area to water, traffic, or chemicals.

Packaging and Storage:

- Packaging: The resin kit is typically available in containers suitable for the specified amount of grout needed. It may be packaged in separate containers for the resin and hardener.

- Storage: Store the resin kit in a cool, dry place, away from direct sunlight. Ensure that containers are tightly sealed when not in use to preserve the quality of the product.

Safety Precautions:

- Protective Gear: Wear gloves, goggles, and protective clothing during mixing and application to avoid skin and eye contact.

- Ventilation: Ensure adequate ventilation in the work area to avoid inhaling fumes from the resin and hardener.

- First Aid: In case of contact with skin or eyes, rinse immediately with plenty of water. If ingested or inhaled, seek medical attention promptly.

Environmental Considerations:

- Eco-Friendly: Formulated with low VOC content to minimize environmental impact and ensure safety during indoor use.

- Disposal: Dispose of any unused resin, hardener, and empty containers in accordance with local environmental regulations.

The Myk SP-100 Resin Kit is a crucial component for creating high-quality, durable, and aesthetically pleasing epoxy grout that meets the demands of various tiling applications.

- CATEGORY: Construction Chemicals

- SUB CATEGORY: MYK Adhesives